5357+ reviews

Order by 16:00 for same day shipping

14 days return

DE

EN

Individual

Business

19/09/2025

Bambu Lab H2D vs H2S: Which Personal Manufacturing Hub is Right for You?

The revolution has begun

You're sitting at your desk. You open your laptop. In just a few clicks, you transform a digital idea into a physical product. No waiting for weeks. No minimum orders. No compromises.

This is the promise of Bambu Lab's H-series printers. It's no longer science fiction.

The H2D and H2S are more than just 3D printers. They are complete manufacturing hubs, blurring the lines between digital design and physical production.

But which of these two powerhouses deserves a spot in your workspace?

Two machines, different personalities

The Bambu Lab H2D and H2S share the same base. But they have completely different personalities.

The H2D is the perfectionist. A machine that knows no compromises. It takes on any challenge. With its dual-nozzle system, it combines materials in new ways.

Think of prototypes with flexible hinges and hard cases. Or artwork that seamlessly blends multiple colors.

The H2S is the pragmatist. For €1299, it offers almost everything its more expensive sibling can. But without the complexity of dual-nozzle printing.

He proves you don't have to spend a fortune. Industrial production is now affordable.

The big difference: One nozzle or two?

Here lies the crux of your decision.

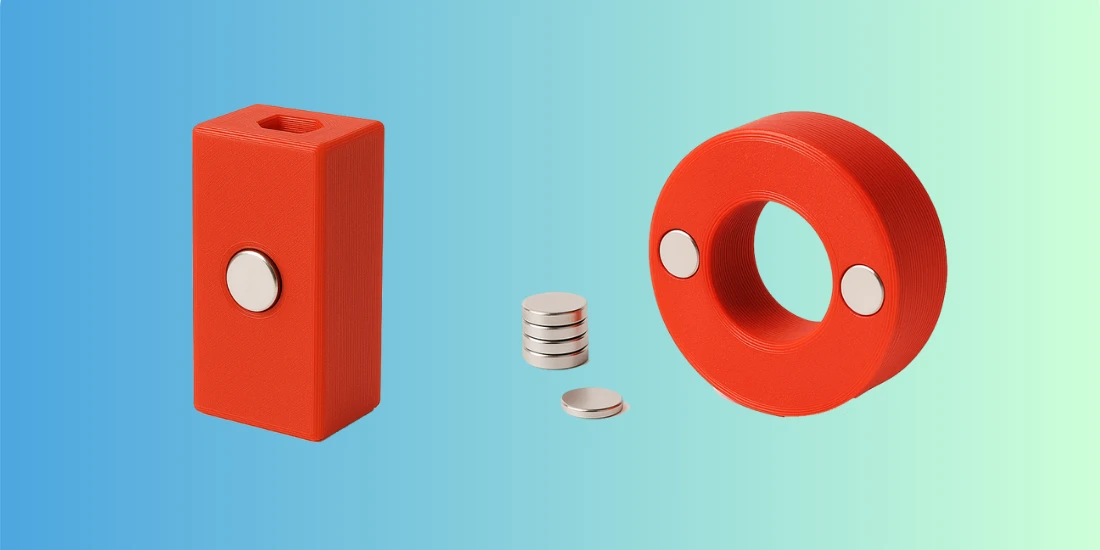

The H2D's dual-nozzle system opens up new possibilities. Imagine printing a drone part. The housing is made of strong ABS. The vibration-damping elements are made of flexible TPU.

Or a prototype where the main material is PLA, but the support structures are made of soluble PVA. After printing, you rinse away the support material.

These opportunities come at a price. Not just financially, but also in complexity.

Each nozzle has its own temperature. Its own flow rate. Its own quirks.

It's like driving a Formula 1 car versus a Tesla. Both get you where you want to go. But one requires more expertise.

The H2S opts for elegant simplicity. One nozzle. One material at a time. But with the same precision and reliability.

For most makers, this is enough. You can still print anything you want, from functional tools to artistic creations.

You just don't combine materials within one print.

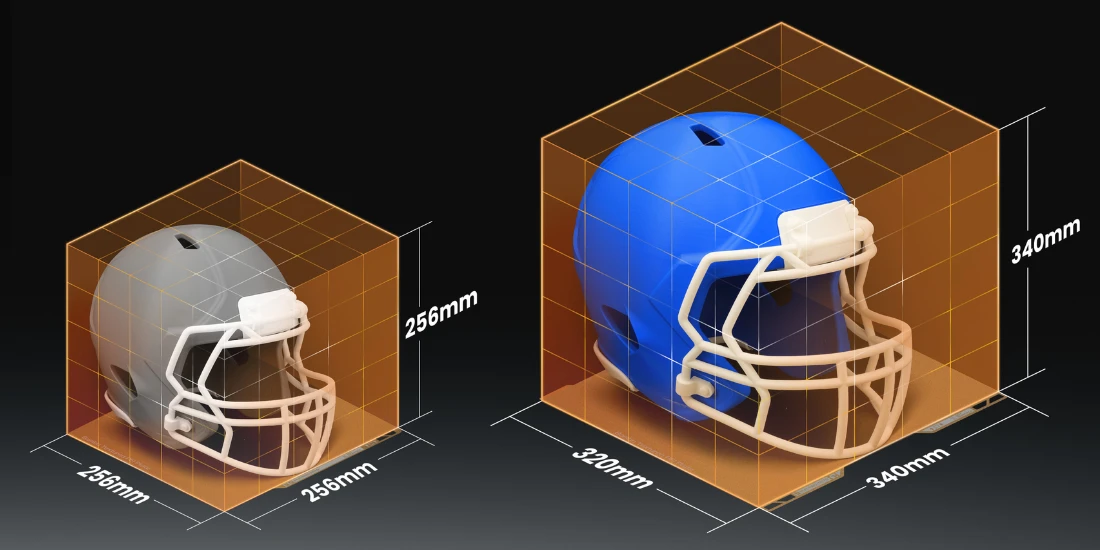

Thinking Big: The Building Volume

Both machines share the same build volume: 350 x 320 x 325 mm.

This isn't a marketing gimmick. This format changes what's possible.

Where you previously had to break large projects into pieces, you can now print complete assemblies. In one go.

A furniture maker can now 3D print entire drawers. An engineer can create complete enclosures. Without seams.

An artist can create sculptures that were previously impossible on desktop printers.

The large volume isn't just convenient. It's liberating.

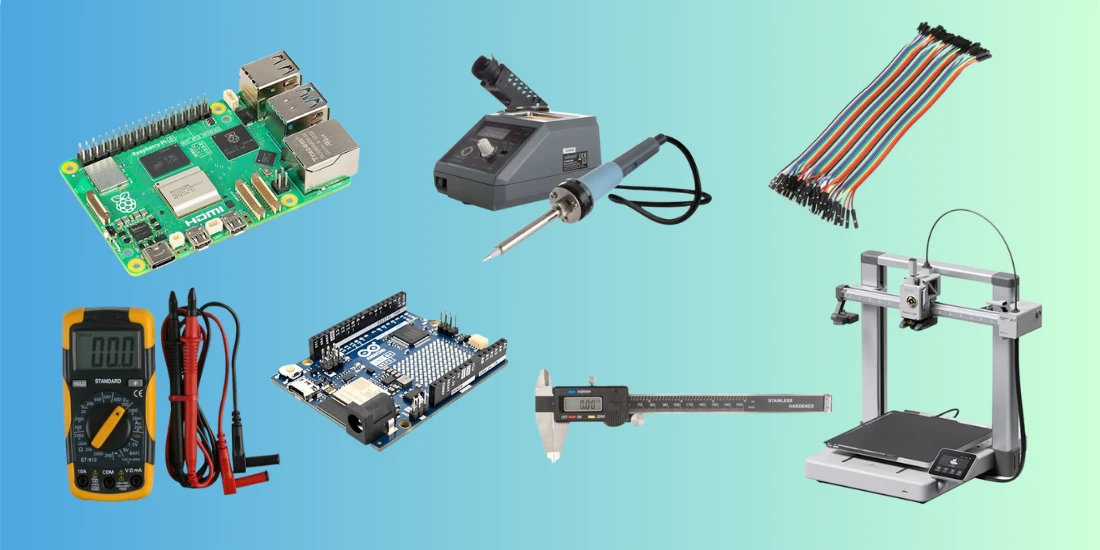

Beyond 3D Printing: The Multifunctional Revolution

Here's where things get interesting. Both machines can be equipped with a 10W laser module.

Suddenly, you no longer have a 3D printer. But a complete fabrication studio.

In the morning, you print a wooden toy. In the afternoon, you engrave a name on it. In the evening, you cut the packaging to size.

This multifunctionality is the future. Instead of different machines for different tasks, you have one system that can do it all.

It saves space. It saves money. And most importantly, it saves time.

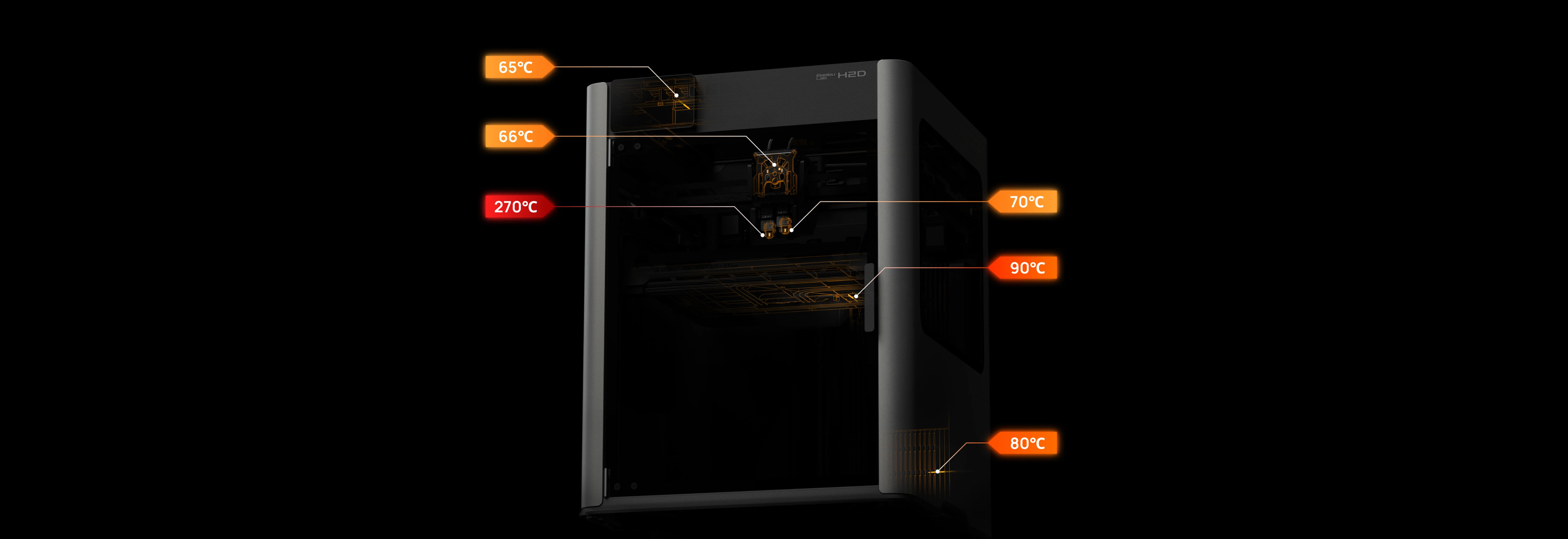

Temperature: The key to material freedom

Both machines can reach temperatures of up to 350°C. This opens the door to new materials.

Materials once reserved for industrial machinery. PEEK for medical applications. Carbon fiber composites for drone parts. PEI for components that must withstand extreme temperatures.

The heated chamber reaches temperatures up to 65°C, making it possible to print even large quantities of sensitive materials.

No more warping. No more cracking. No disappointments after hours of printing.

It's the difference between hoping your print will work and knowing it will.

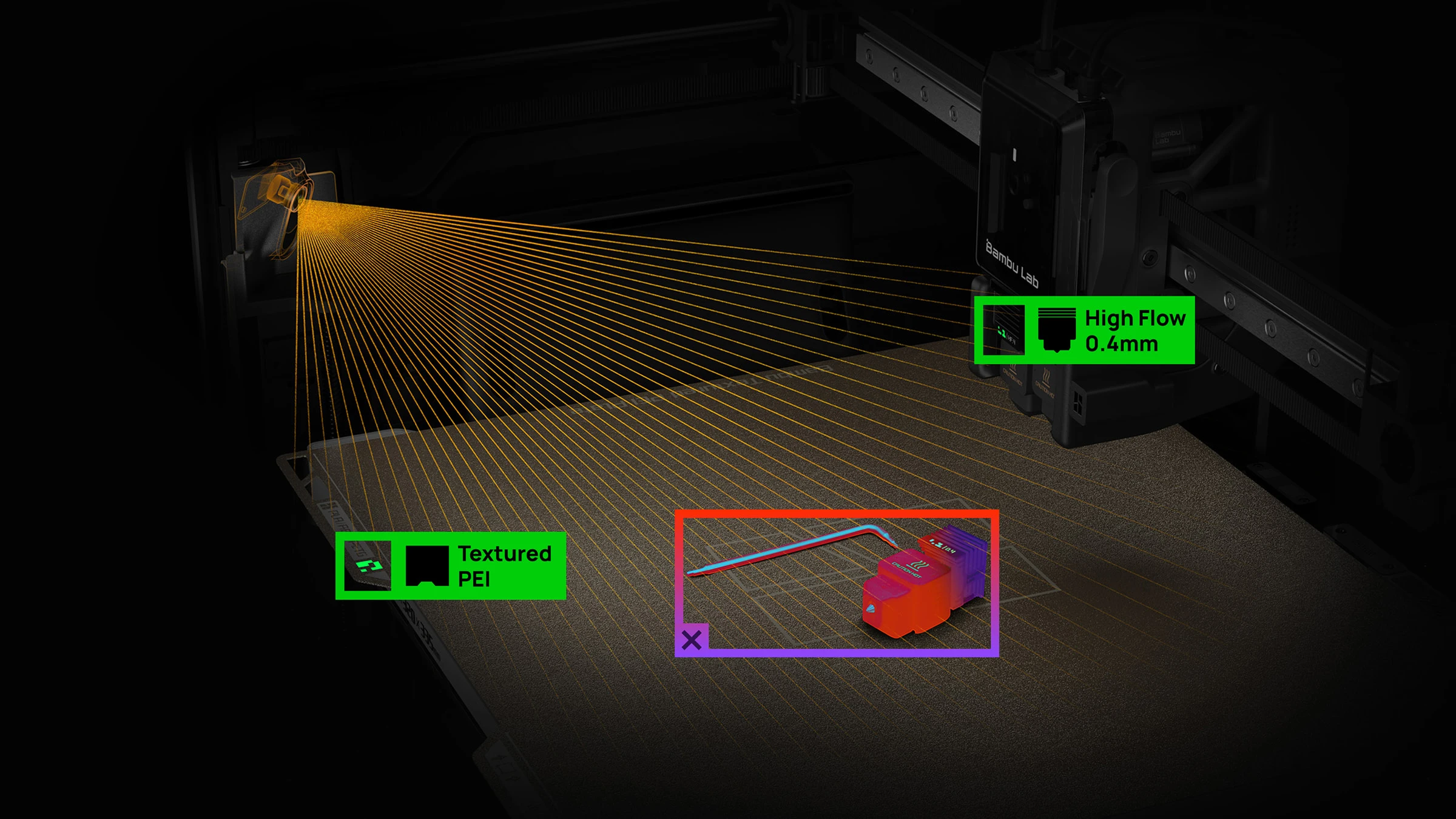

Software: Where magic meets technology

Bambu Studio isn't just a slicer. It's your creative partner.

The software understands what you want to create and automatically sets the optimal settings.

Multi-material prints that used to take hours of setup are now simple. Drag and drop.

The cloud integration is convenient. You can initiate prints from your phone while you're at lunch and come home to a finished project.

The AI-powered monitoring keeps an eye on things. It alerts you if something is about to go wrong.

The Practice: What Does It Feel Like?

The H2D demands patience and precision. It's a tool for those who strive for perfection.

You must be willing to invest time in mastering all the possibilities.

Every new material combination is an experiment. Every successful print is a victory.

The H2S is instantly accessible. Unpack it. Plug it in. You'll be printing your first project within an hour.

It's designed for people who want results. Without the hassle.

That doesn't mean he's less capable. Just that those capabilities are more accessible.

Safety: No compromises

Both machines take safety seriously. Five independent flame sensors. Automatic emergency stop. Flame-retardant materials.

You can print with peace of mind, even during long nighttime sessions.

The laser safety is equally well-thought-out. Automatic shutdown upon opening. Protective filters. Interlock systems.

Laser engraving is as safe as possible.

The financial reality

The H2S for €1299 is a steal for what you get.

Compare it to professional laser engraving machines. Or industrial 3D printers. You realize you're gaining access to capabilities that used to cost tens of thousands of euros.

The H2D costs more. But it also offers more.

It's ideal for companies that need multi-material prototyping. For makers who don't want to accept limitations, its functionality justifies the investment.

Who chooses what?

The H2D is for the perfectionist. The professional. The creator who accepts no compromises.

It's perfect if you regularly combine different materials, if you work with soluble supports, or if you simply want the best of the best.

Then the H2D is your machine.

The H2S is for anyone who wants the power of modern manufacturing without the complexity.

Hobbyists who want to create large projects. Small businesses that need prototypes. Makers looking for multifunctional capabilities at an affordable price.

The future in your hands

Both machines represent a fundamental shift in how we think about making and producing.

They democratize manufacturing. They bring industrial possibilities within reach of individual creators.

The choice between H2D and H2S isn't better or worse. It's a matter of what suits your way of working.

Both open doors to possibilities that were unthinkable a year ago.

The decision

Ultimately, it comes down to one question: What do you want to create?

If the answer is "everything," you're willing to invest in mastering advanced techniques. Then H2D is calling your name.

If the answer is "plenty, but without the hassle," then the H2S is your perfect partner. For €1299, you gain access to a world of possibilities that were once unaffordable.

Whichever you choose, you'll enter a new world. A world where the only limit is your imagination. Where every digital idea can become a physical reality.

The future of making is here. And it fits on your desk.