5368+ reviews

Order by 16:00 for same day shipping

14 days return

DE

EN

Individual

Business

29/10/2025

High-Performance 3D Printing: Filament Types, Applications, and Tips

What makes filament 'high performance'?

Not all 3D printing filaments are created equal. PLA, PETG, and ABS are popular with hobbyists and semi-professionals. However, there are also truly high-performance 3D printer filaments. This material is designed for tough conditions. It remains strong under high heat, heavy loads, chemical exposure, and outdoor use.

The difference lies in the properties. High-performance filaments are made of industrial polymers, such as PEEK, PEI (Ultem), polycarbonate, and technical nylons. These materials are also used in machine parts, medical devices, and aircraft components. They offer strength, dimensional stability, chemical resistance, and a long service life.

Why is this important?

Functional components must be reliable. Think of a housing for a hot machine. Or an outdoor component that endures years of sun and rain. Or a tool that is frequently sterilized. PLA or PETG fall short in these situations.

Advantages

- Heat and wear resistant up to above 100 °C

- Resistant to solvents, oils and fuels

- Retains shape and strength for years

Differences with standard materials

PLA is easy to print, but brittle. It deforms at 60°C. PETG is tougher, but less heat and chemical resistant. ABS performs slightly better, but lags behind true high-performance materials.

Additional requirements when printing

Polycarbonate, PEEK, and carbon fiber-reinforced nylon place higher demands on the printer. They require high printing temperatures, a heated print chamber, and wear-resistant nozzles. These filaments must be stored dry and dust-free.

Printing takes more effort, but it produces strong, durable parts. These parts continue to function, even after years of intensive use.

High-performance filament is less suitable for beginners. For professionals and experienced makers, it opens up new possibilities. Applications previously only feasible with expensive industrial methods are now within reach.

These materials allow you to create parts that not only look beautiful but also withstand extreme conditions. They're the best choice for those who want to go beyond prototyping or decoration.

Properties of high-performance filament

High-performance filaments have improved mechanical, thermal, and chemical properties. These are significantly better than those of standard materials. This ensures that components remain strong and reliable, even under harsh conditions.

A primary characteristic is their high mechanical strength. These filaments often have high tensile strength and strong impact resistance. They withstand repeated use and sudden loads. This makes them ideal for components subject to structural loads or where safety is a priority.

Heat resistance is a second advantage. PLA deforms at 60°C. High-performance materials often retain their shape to over 100°C. Some variants remain stable to over 200°C. An example is Fiberon's PPS-CF10, which retains its shape to over 250°C. This makes them suitable for parts that must withstand heat, friction, or industrial processes.

Chemical resistance is also important. Many materials can withstand solvents, fuels, oils, and acids without losing strength or shape. This is a major advantage in the automotive, medical, and industrial sectors.

In addition, these filaments have excellent dimensional stability. Components retain their shape, even under temperature fluctuations or prolonged loading. Combined with their wear resistance, this results in prints that last for years without loss of performance.

In summary, high-performance filaments offer:

- High mechanical strength and impact resistance

- Excellent heat, chemical and abrasion resistance

- Long-term shape and performance maintenance

These qualities make them perfect for demanding applications. However, they do require a printer that can handle higher temperatures. The printing process also demands a higher-quality machine.

Popular types of high-performance filament and their applications

High-performance filament isn't a single material. It's a collective term for engineering plastics with unique properties and applications. Choosing the right filament depends on the requirements for the end product, such as the required strength, heat resistance, or chemical resistance.

Nylon (PA)

Nylon combines strength, flexibility, and abrasion resistance. It can withstand shock and repeated flexing well, making it popular for gears, hinges, and cable guides. Nylon is resistant to many oils and chemicals. It does absorb moisture, so dry storage and printing are essential.

Polycarbonate (PC)

Polycarbonate is rigid, impact-resistant, and very strong. It does not deform at temperatures above 110°C. These properties make it suitable for machine parts, protective covers, and robust housings.

PEEK and PEI

PEEK and PEI are among the top high-performance filaments. They are used in aerospace, medical, and high-end mechanical engineering. Both materials combine extreme strength with chemical resistance. They retain their shape well above 200°C. Printing requires very high temperatures and a heated print chamber. This makes them particularly suitable for industrial printers. Currently, PEEK and PEI cannot be printed with Bambu Lab printers, for example.

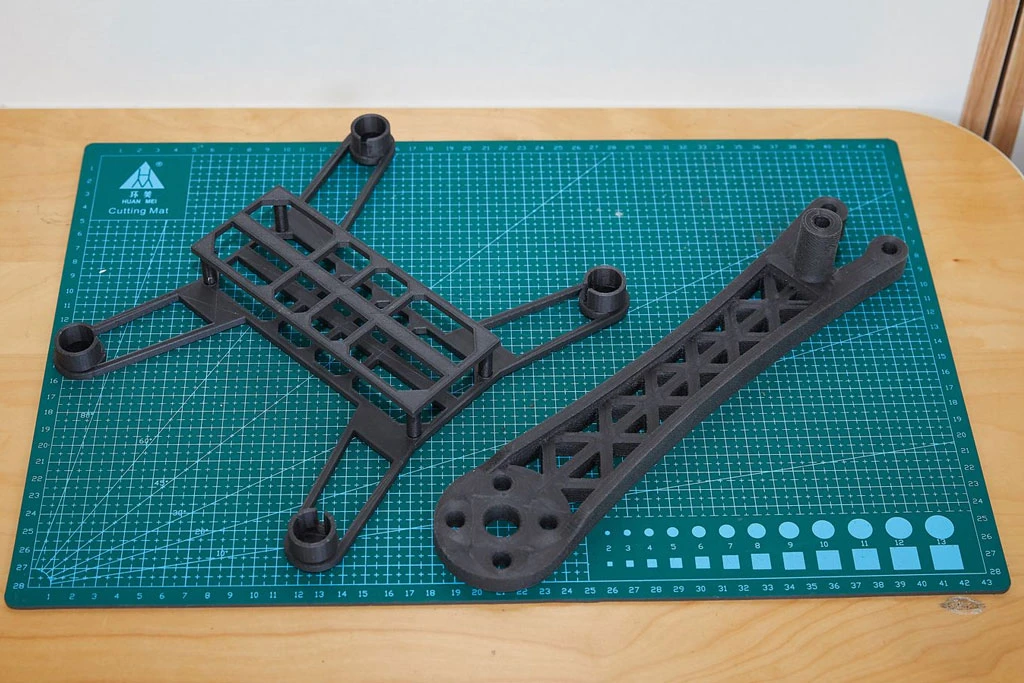

Carbon fiber-filled filaments

Many technical filaments have a short-carbon fiber variant. These fibers stiffen the material, reduce warping, and provide a matte, professional look. They are popular in drones, automotive parts, and applications where weight savings is important.

ASA

ASA is an alternative to ABS with improved UV resistance, making it ideal for outdoor use. It is used in housings, clamps, and components that withstand sun and weather. ASA combines impact resistance with the ability to create sleek, functional prints.

These materials allow manufacturers to print parts that perform in the toughest environments. The right choice depends on the application and the requirements of the part.

Printing challenges and requirements for high-performance filament

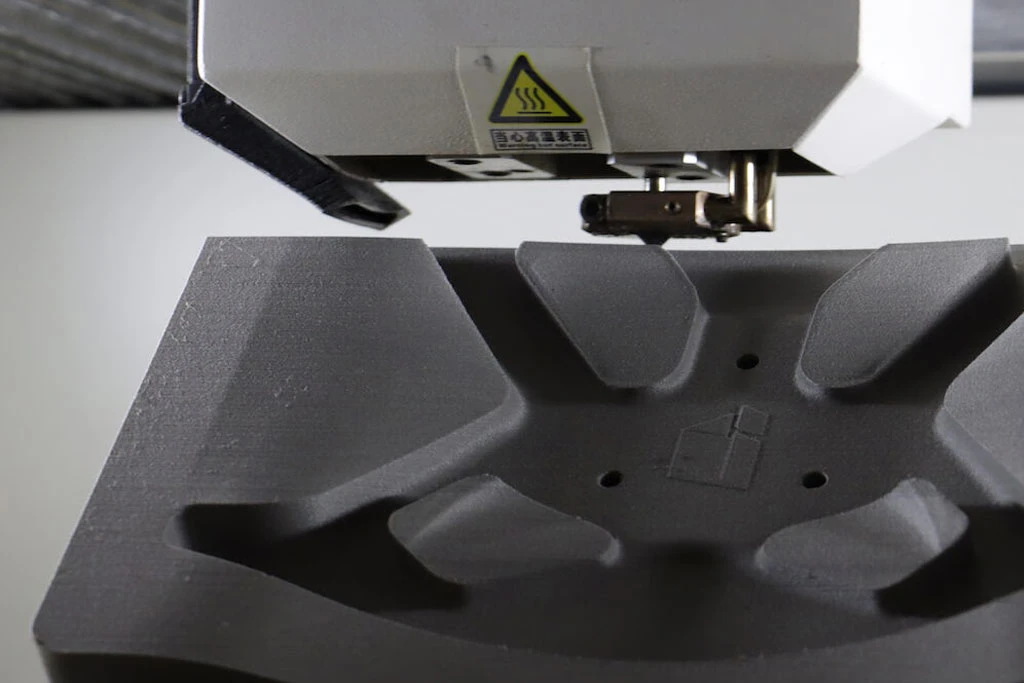

Printing with high-performance filament requires more preparation and technical expertise than working with PLA or PETG. These materials are designed for extreme performance, placing high demands on the printer and the working environment.

One of the biggest challenges is the high printing temperature. Many types require a nozzle temperature between 250 and 400°C. Not every printer can handle that. The nozzle itself is also important. With abrasive additives, such as carbon fiber, a standard brass nozzle wears out quickly. Therefore, use hardened steel or ruby to prevent wear.

A heated print bed is often essential. Temperatures typically range between 80 and 120°C. This prevents warping and ensures good adhesion of the first layers. For materials like PEEK or PEI, a heated print chamber is even necessary. A stable ambient temperature reduces tension in the material and helps maintain its shape during printing.

Moisture poses another challenge. Many high-performance filaments are hygroscopic. They quickly absorb moisture from the air. This can lead to porous layers, poorer adhesion, and lower strength. A filament dryer prevents this problem.

Printing speed also requires attention. These materials are often stiffer and have a higher melting temperature. Printing too quickly can lead to poor layer adhesion. Working slower and using the correct layer height ensures strong, reliable prints.

Applications in various sectors

High-performance filament is chosen when standard materials fall short. These filaments offer strength, heat resistance, and chemical resistance. This makes these materials ideal for a wide range of industries.

Industry and production

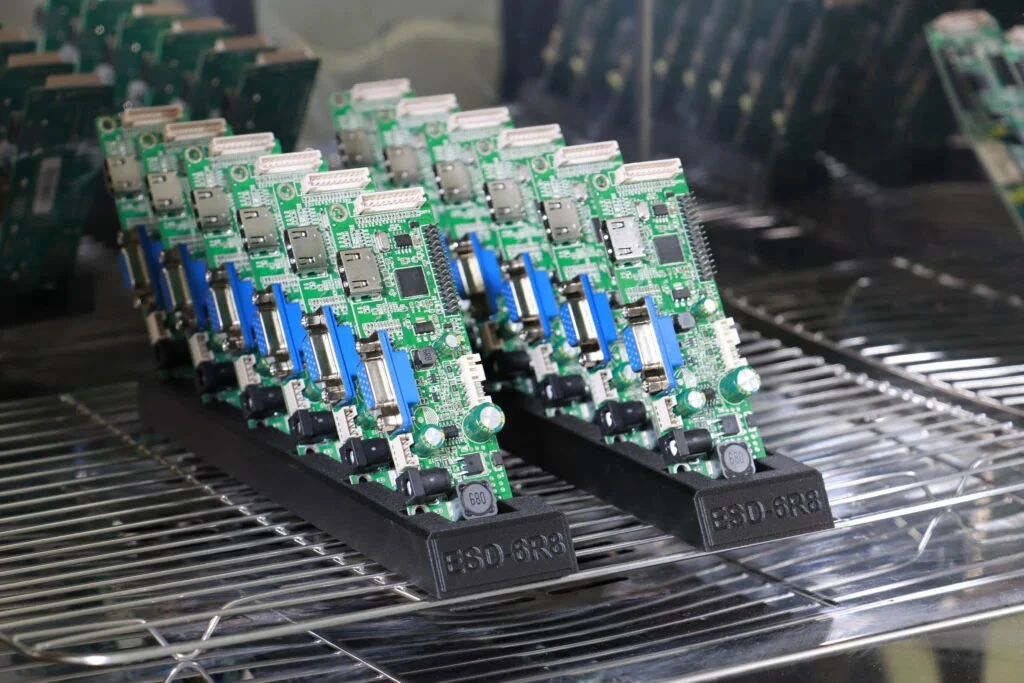

In factories, they are used for functional components and replacement parts. Think of machine components that are subjected to continuous stress, or accessories that must withstand heat and wear. Because they retain their dimensionally stable properties, they are perfect for precision parts that require an exact fit.

Automotive

The automotive industry demands parts that can withstand heat and chemicals. These filaments are used for air intakes, clips, and engine mounts. They are also ideal for parts that come into contact with fuels and oils.

Medical sector

Materials like PEEK and PEI can often be sterilized without loss of strength. This makes them suitable for instrument holders and medical devices, as well as for patient-specific implants in research.

Aviation

In aircraft, weight and reliability are paramount. Carbon fiber-reinforced filaments and heat-resistant polymers are ideal for this. They enable lightweight, strong, and durable components that meet stringent safety requirements.

Consumer and outdoor applications

ASA is popular for outdoor use. It is UV-resistant and remains strong in varying weather conditions. It is used for housings, clamps, and products that will be outdoors for years. Manufacturers also use it for functional parts that need to last.

Tips for the best printing results with high-performance filament

Printing with high-performance filament requires the right printer, appropriate settings, and careful preparation. Small details often determine whether the final result is mediocre or excellent.

Dry the filament

Many high-performance materials quickly absorb moisture. This causes bubbles, poor layer adhesion, and reduced strength. Dry the filament for several hours in a filament dryer or at a low temperature in an oven. Store it in a sealed, heated enclosure during printing to prevent moisture absorption.

Adjust the print speed

A lower print speed ensures better layer adhesion and less internal stress. This is important for stiff materials and high melting temperatures. Take your time for strong, consistent prints.

Limit active cooling

For many technical materials, it's better to turn off the cooling fan or run it at a low speed. This improves adhesion between layers and prevents warping.

Make test prints

Always perform small test prints before making the final part. This helps you find the ideal balance between temperature, speed, and layer height. This saves material and prevents failed prints.

Consider post-processing

Some materials, such as nylon or PEEK, benefit from annealing. This is a controlled heating process that reduces internal stresses and increases strength. Sanding, polishing, or coating can also improve durability and appearance.

Sustainability and cost consideration

High-performance filament often costs more than standard materials. The higher price is due to more expensive raw materials, more complex production, and smaller print runs. However, the purchase price doesn't tell the whole story.

A PLA or PETG component may seem inexpensive at first. But if it wears out, deforms, or is chemically damaged after a few months, additional costs follow. Replacement means new material, additional labor, and sometimes production downtime. Components made of high-performance filament often last for years without loss of quality. This often makes the higher price a wise investment, especially in sectors where reliability is crucial.

Sustainability also involves efficient use of materials. Because high-performance filaments are stronger and more resistant to stress, less material can sometimes be used without sacrificing performance. This shortens printing time, saves filament, and reduces energy consumption.

Waste and reuse also play a role. Some technical filaments are recyclable or can be reprocessed within your own production process. This is attractive for companies looking to reduce their environmental footprint without compromising quality or performance.

If you only look at the price per kilo, you'll mainly see the higher initial cost. However, if you look at the bigger picture, you'll often see that high-performance filament is more cost-effective and sustainable in the long run.

Conclusion

High-performance filament offers much more than standard 3D printing materials. It combines strength, heat resistance, chemical resistance, and dimensional stability. This makes it ideal for applications where reliability and longevity are paramount.

Professionals and experienced makers can use this to create parts that last for years. These parts remain strong, even under heavy loads. They meet stringent functional requirements. While the initial purchase price is higher, it often pays for itself. Fewer replacements mean lower costs and less downtime.

Success begins with proper preparation. Choose a printer that can handle high temperatures. Use a durable nozzle. Ensure a stable printing environment. Store filament dry and clean to maintain quality. Master the entire printing process for consistent results.

Beginners are best off starting with a forgiving technical filament. For example, choose PETG with carbon fiber or nylon. These materials perform better than PLA or standard PETG and are easier to print. Experienced users can switch to polycarbonate, PEEK, or PEI. This does require some knowledge and a suitable printer.

High-performance filament opens doors to new applications. In industry, it enables strong machine parts. In the automotive sector, it produces heat- and chemical-resistant clips and holders. In the medical world, it enables sterilization-resistant instruments and aids. For outdoor use, it offers durable, UV-resistant products that last for years.

The difference lies in long-term performance. A standard part can wear out or deform after months. A part made of high-performance filament remains strong and reliable.

Investing in knowledge, equipment, and meticulous processes yields a significant return. The reward is a print that excels in quality, durability, and performance.

.png)